The Hidden Consequences of Voltage Drop in Relay Contacts

페이지 정보

본문

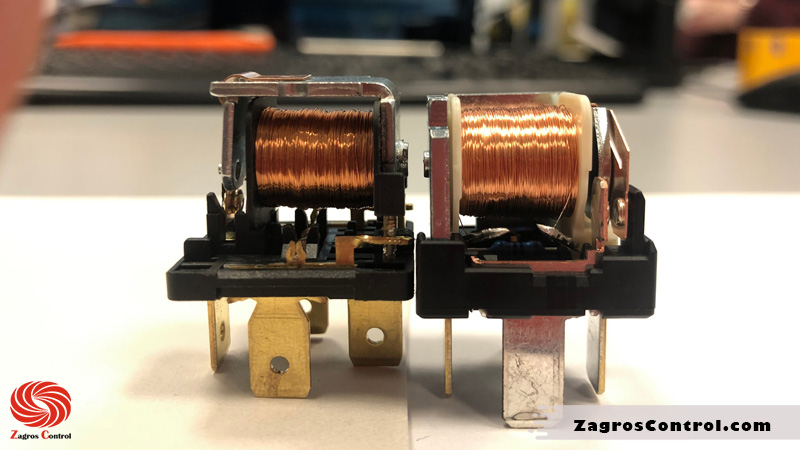

When electrical current flows through a relay contact, a small voltage drop occurs across the contact surfaces

Even a few millivolts of loss may trigger malfunctions in sensitive electronic environments

The drop happens because even the best conductive materials used in relay contacts have some inherent resistance

Energy dissipation due to contact resistance translates directly into a voltage differential across the relay terminals

Under substantial amperage, even minor resistances produce measurable voltage losses

In applications like motor controllers or heating circuits, resistances as low as 50 milliohms can yield drops exceeding 300 mV

Devices like PLC inputs, CAN bus modules, or analog transducers may misinterpret signals due to insufficient voltage levels

A sensor that expects a 5 volt signal might only receive 4.7 volts, leading to inaccurate readings or false triggering

Another concern is the long term effect of voltage drop

Cyclic high-current operation accelerates material loss and انواع رله the formation of insulating oxide layers

This increases the contact resistance, which in turn increases the voltage drop

As the resistance grows, the heat generated also increases, creating a feedback loop that can accelerate contact degradation

Prolonged degradation may result in welded contacts that fail to open, or open-circuit conditions with no current flow

Temperature also plays a role

Operating near maximum temperature specs with added internal losses risks component failure

This is especially problematic in enclosed control panels with poor ventilation

Thermal stress from combined sources can lead to unexpected, early-stage relay collapse

Designers must prioritize relays with sub-50mΩ contact resistance and match ratings to peak current demands

Opting for specialized contact alloys like AgSnO₂ or AgZn enhances both electrical performance and mechanical longevity

For mission-critical systems, combining snubber circuits with SSRs eliminates mechanical wear entirely

Regular maintenance and inspection of relays in high duty cycle environments can also help catch early signs of contact degradation

Comparing source voltage to load voltage during active switching exposes unacceptable drops

Understanding and addressing relay contact voltage drop is essential for ensuring reliability, accuracy, and safety in electrical systems

- 이전글2025 Paris World Cup in March 25.10.09

- 다음글미래의 미래: 기술과 사회의 진화 25.10.09

댓글목록

등록된 댓글이 없습니다.